Innovative Coolant Filtration Systems for Industrial Efficiency

KingNice Technology specializes in coolant filtration systems, CNC oil skimmers, and sump tank cleaning machines—solutions engineered to boost operational efficiency and meet environmental standards.

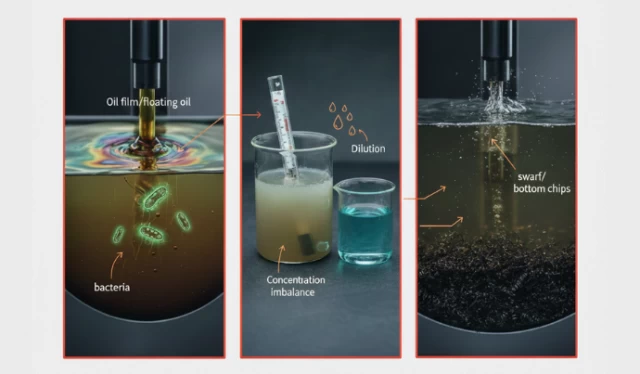

Our CNC oil skimmer removes floating oil from coolant in CNC machining processes, while our coolant filtration systems preserve coolant clarity and extend service life.

Sump tank cleaning machines ensure cleaner, more stable machine operation by removing sludge and sediment. Explore our products below to find the solution that fits your needs.

Traditional CNC oil skimmer use mechanical principles but are slow and have limited efficiency. KingNice oil-water separator uses a special media module to quickly separate oil and coolant, ensuring that water resources are not polluted and reused simultaneously.

CNC Machine Processing stopped!

WHY CHOOSE KINGNICE?

50+

SALES COUNTRY

85%

COST SAVINGS

1000+

SOLD PER YEAR

KingNice Technology - Innovators in Industrial Solutions, Oil and Water Separators. We are spreading our passion and expertise around the world. You are welcome to be part of advanced production system manufacturers. We are also looking for agents or partners who share the same concept and passion with us.

Discover MoreKingNice Technology's products are widely used in machinery manufacturing, aerospace, automotive, and precision machining.

_Resize Image.webp)

.webp)