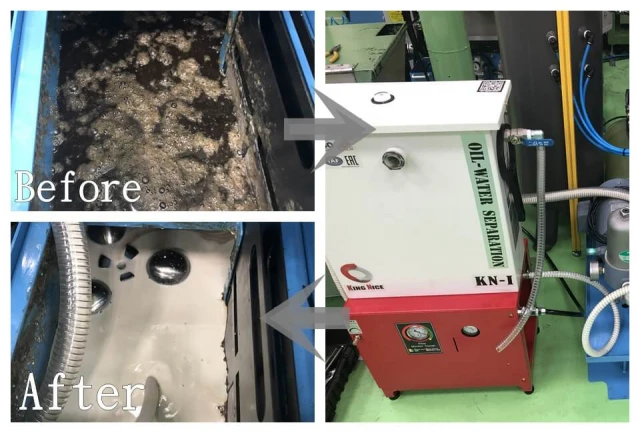

CNC Coolant Oil Separator

Oil and Water Separator Machine - KN-I

KingNice Technology specializes in industrial liquid treatment, offering eco-friendly solutions for oil-water separation. With proven expertise in coolant filtration and filtration separation, the company develops high-efficiency systems designed to treat and recycle contaminated fluids from machining environments.

Its three core product lines focus on:

-

Removing emulsified oil

-

Suspended solids

-

Waterborne contaminants from coolant, enabling purification and recirculation in machine tool operations.

The KN-I Oil and Water Separator is engineered for a wide range of CNC cutting fluid applications. It efficiently removes floating oil from coolant tanks, helping extend fluid life and maintain a clean system environment. The CNC Coolant Oil Separator improves separation efficiency, ensuring stable operation and long-term system performance.

Key benefits include:

-

Lower failure rates and fewer defective parts in CNC machining

-

Reduced water and coolant consumption

-

Less downtime and lower labor costs

-

Consistent coolant levels and controlled tank temperature

1. Effectively removes slide oil, tramp oil, and floating debris from the coolant tank surface

➤ A reliable Coolant Skimmer solution for maintaining clean fluid circulation and reducing oil-water emulsification odors

2. Reduces oil mist and airborne droplets that lead to residue on machines and workpieces

➤ The Oil Skimmer CNC setup helps improve workplace cleanliness and minimize skin irritation risks

3. Operates without requiring an external discharge system

➤ The CNC Oil Skimmer minimizes waste oil generation and lowers wastewater treatment costs

4. Prevents corrosion and rust on machined parts

➤ Ensures machining precision and extends tool lifespan, especially in systems using a CNC Coolant Skimmer

5. Maintains stable coolant quality and consistent filtration performance

6. suspended solids to protect pumps and motors and reduce contamination on workpieces

7. Suppresses anaerobic bacterial growth

➤ Helps reduce the frequency of coolant replacement and fluid degradation

8. Minimizes clogging in coolant piping and motor systems

9. Reduces manual cleaning time and labor costs

➤ Supports efficient filtration separation and coolant recovery operations

Turn Dirty Coolant into Smart Savings

84%

COST SAVINGS

90%

DISPOSAL COSTS

91%

TIME SAVINGS

|

Item Model

|

KN-I | Unit |

|---|---|---|

| Machine Size | 440X250X870 | mm |

| Net Weight | 28 | kg |

| Capacity | 32 | L |

| Effiency Capacity | 720~1200 | L/h |

| Timer System | NO | - |

| Air Inflate System | NO | - |

| Unit Waste Oil Tank | 3.5 | L |

| Extra Waste Oil | Optional | - |

| Air Pump | 1.6BAR | min |